Your recovery/recycling machine has r-22 refrigerant in it – Your recovery/recycling machine contains R-22 refrigerant, a substance with significant environmental implications. Understanding its properties, handling, and disposal is crucial for responsible ownership and compliance with regulations. This comprehensive guide delves into the essential aspects of R-22 refrigerant management, empowering you to make informed decisions and contribute to a sustainable future.

R-22 refrigerant, a hydrochlorofluorocarbon (HCFC), has been widely used in refrigeration and air conditioning systems due to its efficient cooling properties. However, its ozone-depleting potential and high global warming potential have raised environmental concerns, leading to regulations phasing out its production and use.

1. R-22 Refrigerant Background

R-22, also known as chlorodifluoromethane (CHClF2), is a hydrochlorofluorocarbon (HCFC) refrigerant that has been widely used in refrigeration and air conditioning systems since the 1930s. It is a colorless, non-flammable gas with a boiling point of

- 40.8°C and a freezing point of

- 157.2°C. R-22 is a potent greenhouse gas with a global warming potential (GWP) of 1810, meaning it has 1810 times the global warming effect of carbon dioxide over a 100-year period. It also has an ozone depletion potential (ODP) of 0.055, contributing to the depletion of the Earth’s protective ozone layer.

2. Environmental Impact of R-22

Due to its high ODP and GWP, R-22 has been phased out in many countries under the Montreal Protocol and other environmental regulations. In the United States, the production and import of R-22 was banned in 2020, and its use in new equipment is prohibited.

The remaining R-22 in existing systems must be recovered and recycled or disposed of properly to minimize its environmental impact.

3. Recovery and Recycling of R-22

Recovering and recycling R-22 from old appliances is crucial to prevent its release into the atmosphere. This process involves extracting the refrigerant from the system using specialized equipment and cleaning and purifying it for reuse. Certified technicians must perform recovery and recycling to ensure proper handling and disposal.

4. Responsible Disposal of R-22 Appliances: Your Recovery/recycling Machine Has R-22 Refrigerant In It

Appliances containing R-22 must be disposed of responsibly to avoid illegal dumping or improper disposal. Contact local waste management authorities or certified recycling facilities for proper disposal options. Some programs and initiatives offer incentives or rebates for responsible disposal of R-22 appliances.

5. Health and Safety Considerations

Handling R-22 refrigerant requires proper safety precautions. Adequate ventilation and personal protective equipment (PPE), such as respirators and gloves, are essential. Avoid direct contact with skin or eyes, and in case of accidental release, ventilate the area and seek medical attention if necessary.

Regular maintenance and inspection of R-22 systems are crucial to prevent leaks and ensure safe operation.

6. Economic Implications of R-22 Phase-Out

The R-22 phase-out has financial implications for businesses and consumers. Replacing R-22 appliances and retrofitting existing systems can be costly. However, long-term savings can be achieved through increased energy efficiency and reduced environmental penalties. Exploring alternative refrigerants and implementing energy-saving measures can help minimize costs.

7. Technological Advancements in Refrigerant Technology

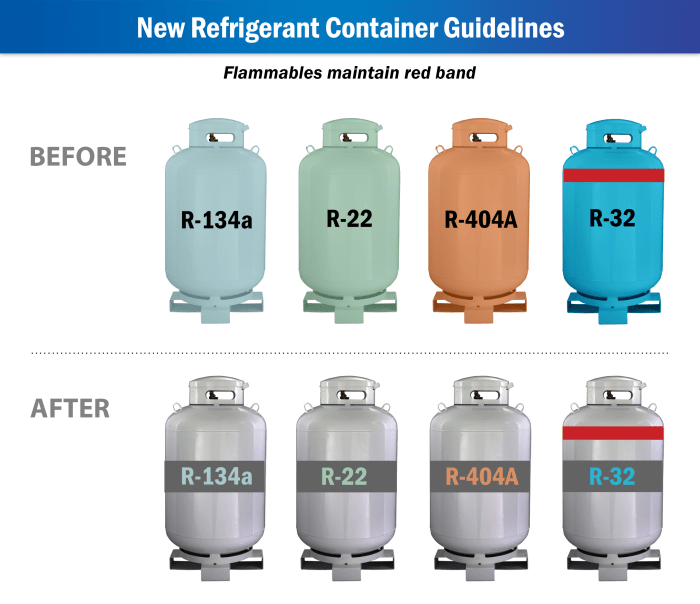

Advancements in refrigerant technology have led to the development of more environmentally friendly alternatives to R-22. Hydrofluoroolefins (HFOs) and hydrofluorocarbons (HFCs) are commonly used as replacements, offering lower GWP and ODP. Research and development continue to explore even more sustainable refrigerants with minimal environmental impact.

8. Best Practices for Managing R-22 Systems

To manage R-22 systems responsibly, follow these best practices:

- Regular maintenance and inspection to detect and repair leaks

- Proper recovery and recycling of refrigerant

- Responsible disposal of R-22 appliances

- Training and certification for technicians handling R-22

- Monitoring and reporting of refrigerant usage and emissions

- Implementation of leak detection and early warning systems

- Collaboration with industry organizations and regulatory bodies

Top FAQs

What are the environmental concerns associated with R-22 refrigerant?

R-22 refrigerant has a high ozone-depleting potential (ODP) and global warming potential (GWP), contributing to ozone layer depletion and climate change.

How can I properly dispose of appliances containing R-22 refrigerant?

Contact certified technicians or local programs that accept R-22 appliances for responsible disposal. Avoid illegal dumping or improper disposal.

What are the safety precautions when handling R-22 refrigerant?

Ensure proper ventilation, wear personal protective equipment (PPE), and avoid direct contact with the refrigerant. In case of accidental release, ventilate the area and seek medical attention if necessary.